-

Mail 2561880819@qq.com

-

Contacts +86-18928672668

+86-757-85213502

Mail 2561880819@qq.com

Contacts +86-18928672668

+86-757-85213502

1. Overview of the integrated aluminium slag treatment system:

1.1 Overview

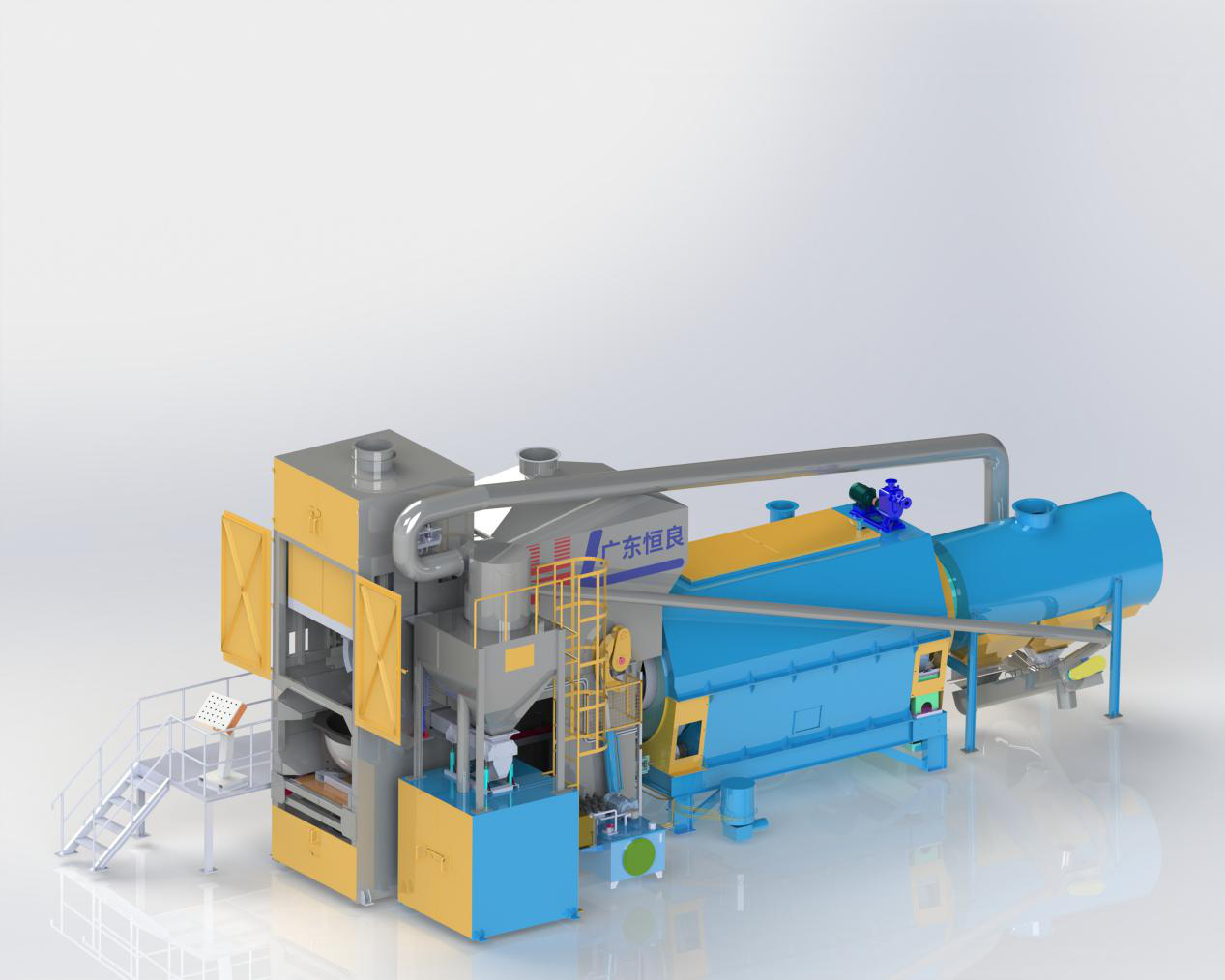

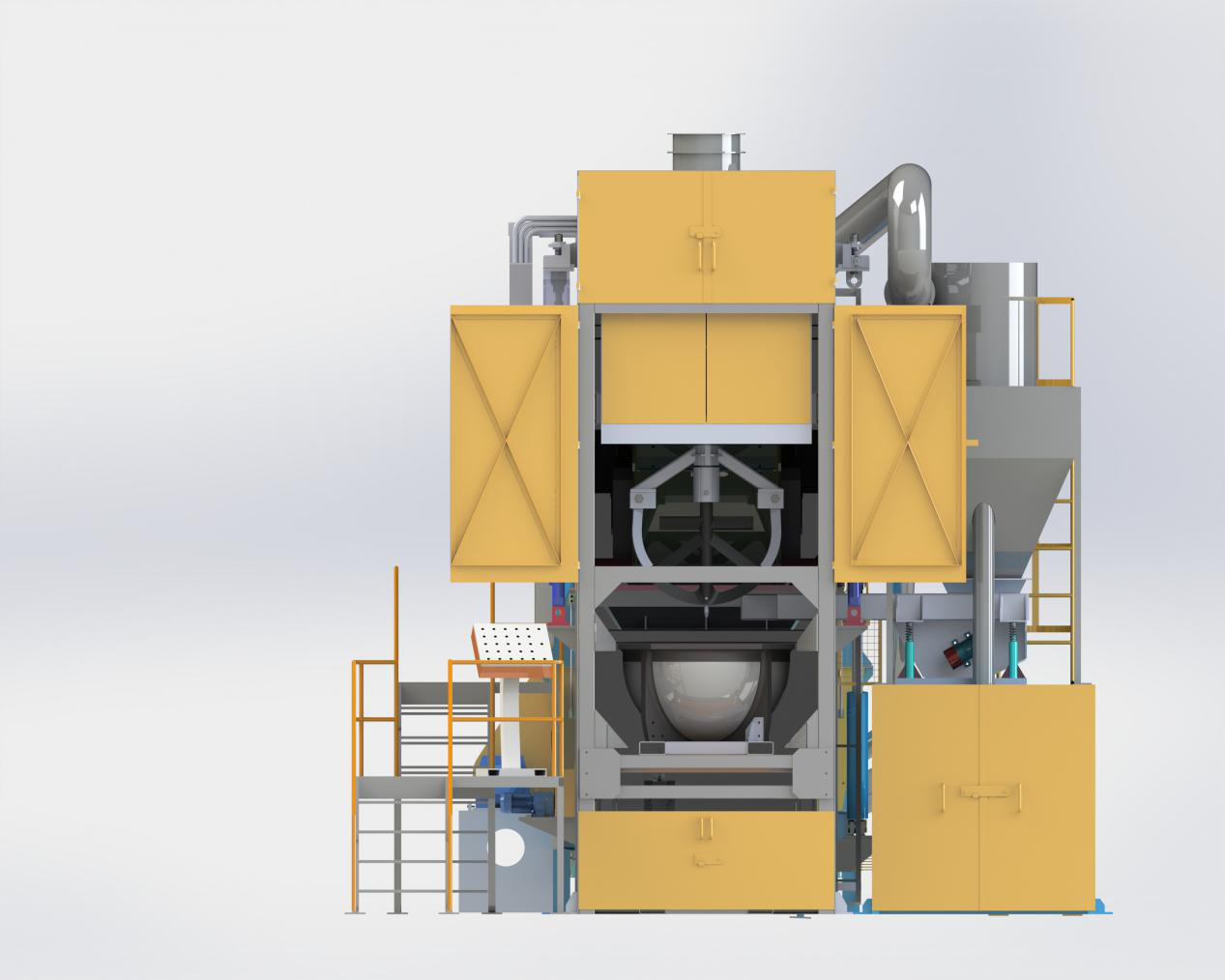

The hot aluminium slag treatment system is an automated production line specially designed for separating and treating aluminium slag (hot slag). It can be used to separate and recycle the available aluminium from the slag produced in the aluminium alloy melting furnace in a hot state and to store the remaining aluminium ash in boxes (bags) after cooling.This equipment has been widely used at home and abroad. The ash processing line produced by our company is an advanced technology in China.The application of this treatment line not only greatly reduces the worker's labor intensity, greatly reduces the pollution of the environment caused by the discharges, but also makes the environmental protection up to the standards by using it in combination with the dust removal. It also greatly improves the recycling efficiency of aluminium slag by enterprises and has remarkable economic benefits. Therefore, it has been vigorously promoted.

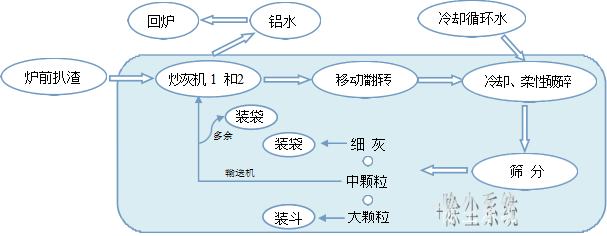

1.2 Process Flow and Equipment Configuration Form

Explain:

1. The liquid aluminium liquid is separated by the aluminium slag processor by stirring the hot aluminium slag. That is to say, the slag is first oxidized and cooled, at the same time, the slag is crushed to a certain degree, and the hot ash after treatment is added to the cold ash bucket to cool the hot ash.Use the dust collector of Party A for centralized dust removal.

2 and 2 frying machines share a set of medium-sized particles cold-ash feeding system, of which all the medium-sized particles come from the frying machine 1.

3 and 2 ash fryers are equipped with 2 cold ash buckets.The two systems share an external water circulation system and a dust removal system, but the circulation needs to be the sum of the two devices.

4. The set of equipment is equipped with three screening systems, among which fine ash is packed and sold out for sale with high content of large particles of aluminum and can be remelted and recycled in the furnace.

5. Forklift feeding and discharging position (the position of the forklift is indicated in the figure) The turning space of the forklift should be taken into account in the layout, and 7 m distance should be reserved in theory (based on 3-ton forklift).

6. Each set of frying ash equipment is equipped with a special remote control, which is simple and convenient, and can also be operated manually on the control box.

Copyright © 2020-2025 Foshan Hengliang Metal Equipment Co., Ltd All Rights Reserved.

粤ICP备20062218号  粤公网安备 44060502002187号

粤公网安备 44060502002187号

Power by: pbinfo.cn

pbinfo.cn

Online

consulting